Tesla's Cybercab Production Targets 10-Second Assembly with Revolutionary Unboxed Method

Austin, Texas – Tesla has unveiled new details regarding its "Unboxed" manufacturing process for the upcoming Cybercab, aiming to drastically cut production times to as little as 10 seconds per vehicle. The reveal showcased the modular assembly approach, which breaks down vehicle construction into distinct, parallel components before final integration. This innovative method is central to the company's strategy for mass-producing its autonomous robotaxi.

The process, a significant departure from traditional automotive assembly lines, involves building a car in several pre-assembled modules, akin to a "LEGO set." As described by Bradford Ferguson on social media, diagrams presented during the reveal illustrated the four primary sections, with "#3" identified as the "top and floor of the car with the trunk and rear tires." Attendees noted that photography was restricted during the tour, emphasizing the proprietary nature of the new process.

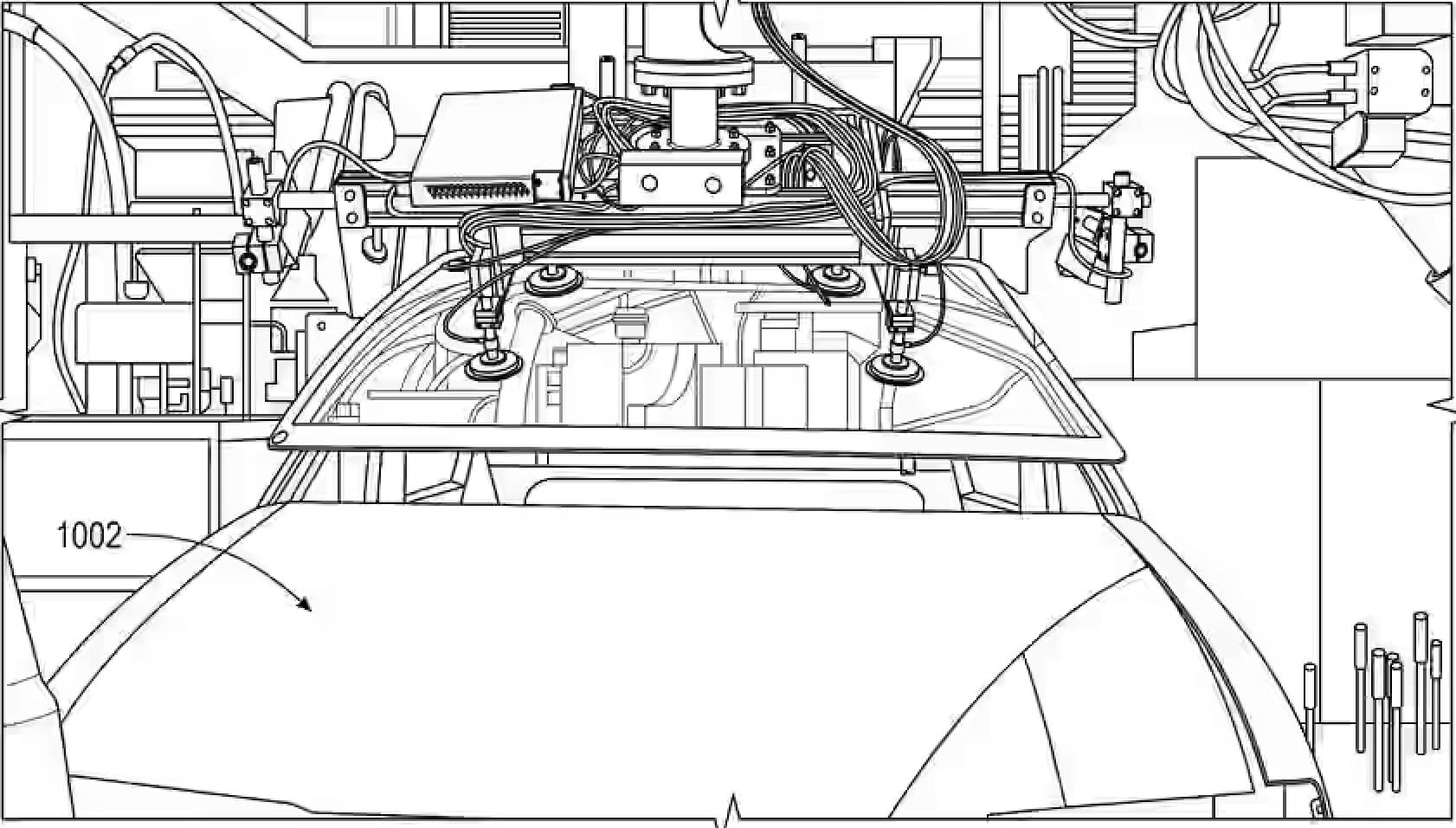

Tesla's Unboxed Method begins with a central "skateboard" platform, which integrates the vehicle's floor and structural battery pack. Heavily pre-assembled front and rear modules are then attached, allowing for simultaneous work on different sections. This parallelization is expected to reduce factory footprints and production costs by up to 50%, while dramatically accelerating manufacturing speeds.

The Cybercab, a compact, two-seat electric vehicle designed for ride-hailing services, is the first model specifically engineered for this production strategy. Tesla CEO Elon Musk has previously stated that the new production line could achieve a cycle time of approximately 10 seconds, with a future path to producing a Cybercab every 5 seconds. This compares to about 34 seconds for a Model Y using traditional methods.

New patents detail the method's reliance on advanced robotics, AI-driven automation, and high-strength industrial adhesives for attaching body panels, replacing traditional welding and screws. This approach ensures precise alignment and further streamlines the assembly. Musk has openly invited rival automakers to adopt the "open-source" patents, highlighting Tesla's belief in the transformative potential of this manufacturing paradigm.